Hot Stamper

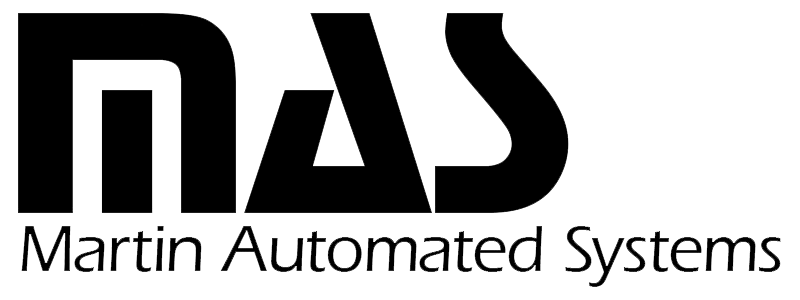

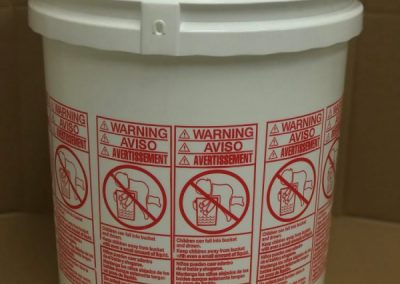

The Martin Automated HST19 automatically hot stamps child safety warning labels on to 11” and 12” round, square or rectangular pails. Available with a single or dual heads. Pails are oriented by a servo motor and offset in the stamping area. Two different labels can be placed at any offset.

Hot Stamping

The pail is lifted to the stamping head, then oriented, then stamped. The stamp location can be offset. And is adjustable to 360 degrees. Temperature control and hot stamp parameters are controlled via the HMI touch screen. When the foil is running low and when the foil has run out, a sensor will indicate this with a warning.

Single Head Hot Stamp

Our standard single head hot stamper. Two different labels can be placed at any offset.

Dual Head Stamp

Hot stamper with two stamp heads that can stamp simultaneously. Two different labels can be placed at any offset.

Flame Treatment

Flame treatment can be enabled and disabled via the HMI touch screen. Also, duration and rotation speed are adjustable via the HMI touch screen. Includes a flame out sensor. If the burner fails to ignite, the pail is held back and a warning screen appears.

Additional Information

Optional square/rectangular pail orientation with actuated flame treatment

Square/rectangular pail types are orientated to the handle mounting hole. The pails are then flame treated by a cam actuated flamer, which traces the shape of the pail. This option provides more consistent flame treatment.

Basic Operation and Summary

A fully automatic system that can perform the following functions

- Infeed loading

- Pail flaming

- Pail hot stamping

- Integrated flame treatment

- Flame out sensor

- Stamp location offset from handle lobes (adjustable to 360 degree)

- Single stamp mode

- HMI integrated temperature control

- Low foil warning

- End of foil warning

- Safety enclosure

Specifications

Power 240VAC 1PH

Amperes 15 AMPS

Air Supply 100 PSI

Ready for a quote?

Ready for a quote? Contact us today!

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Need our Parts and Repair Requisition Form? Click here!

102-17941 Roan Place,

Surrey, BC Canada V3S 5K1

Phone: (604) 576-6000

Fax: (604) 576-6097

Martin Automated Systems’ plant is in beautiful British Columbia, Canada. Located in Surrey, a suburb of Vancouver, we are a 45-minute drive from Vancouver international airport (VYR) and a 15-minute drive from the Pacific Highway border crossing.