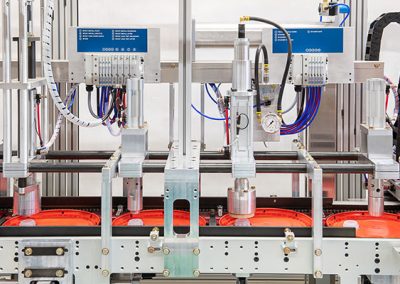

Automated Lid System

The Martin Automated ALS06 automatically installs gaskets and fitments into plastic lids. The Automated Lid System can be built to suit many different configurations for different styles of lids, fitments, and closures.

Infeed options

The Automated Lid System processes lids directly from the injection mold machine or can de-nest stacks of lids.

Lid De-nesting

The lid denester separates a single lid from a stack of nestable lids. Stacks of lids are conveyed up to the denesting station. The lids are then separated and fed into the indexing conveyor of the automated lid system.

Configurations

The ALS06 can process up to three different styles of lids at the same time. The different styled lids are tracked as they enter the machine, different closures and fitments can be installed on each lid. Completed lids are tracked and stacked into three different stacks and accumulated. Each station can be disabled or enabled during production.

Verification and quality control

Lids are indexed in pockets designed to protect the lid from damage. All machines have a gasket verification station. For fitments and closures, the machine incorporates leak testing. Lids that fail any detection station are rejected without any further operation to the lid and will not be stacked.

Control

An HMI touch screen allows parameters to be set – passwords can be assigned for different levels of access and authorization – preventing unauthorized system changes.

Additional Information

Basic Operation and Summary

A fully automatic system that processes plastic lids and can perform the following functions:

- Lid denesting

- O-ring gasket installation and verification

- Flame treatment

- Closure/Fitment installation and verification

- Screw Cap installation and verification

- Stacking

- Optional controls, Siemens, or AB

- Optional index drives, Servo or Rotary

- Can process up to three different lids

- Can be programmed to process multiple styles of fitments or closures

- Lids are indexed in pockets designed to protect the lid from damage

- Each function can be enabled or disabled from the HMI

Typical Closures or Fitments

The machine can accommodate most industrial closures and can support different spout and plug types, which can be easily selected without the shifting of hardware.

Below is a summary of typical closures or fitments:

- Metal Crimp

- All types of plastic press-in spouts

- Tint plugs

- Vents

- Screw Caps

Specifications

Power 120VAC 1PH

Amperes 30 AMPS

Air Supply 100 PSI

Ready for a quote?

Ready for a quote? Contact us today!

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Need our Parts and Repair Requisition Form? Click here!

102-17941 Roan Place,

Surrey, BC Canada V3S 5K1

Phone: (604) 576-6000

Fax: (604) 576-6097

Martin Automated Systems’ plant is in beautiful British Columbia, Canada. Located in Surrey, a suburb of Vancouver, we are a 45-minute drive from Vancouver international airport (VYR) and a 15-minute drive from the Pacific Highway border crossing.