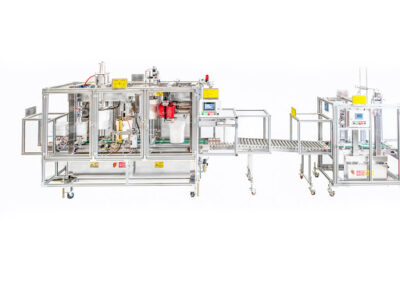

Hotstamper System – Pail Processing Cell

A completely integrated pail processing cell. The system starts with the standard Martin Automated Single Head or Dual Head hot stamper and integrates stations into the machine. All stations parameters can be set by means of an HMI touch screen and each station can be enabled or disabled. We can tailor the processing cell to your requirements. Advantages of the pail cell are that it can save space, is easily moved on casters and will not stamp pails that leak.

Stations that can be integrated into the hot stamper:

Pail Stretcher

Pail Stretcher units are highly effective at improving molding cycle time. Martin Automated Systems manufactures pail stretchers for both square and round pails. The pail stretchers are water-cooled, and the expanding jaws are machined from hard anodized aluminum or optional heat treated stainless tool steel and use Turcite bearings.

UN Leak Tester

The UN leak test option will check pails for small leaks. It monitors the pressure inside by inflating the pail to a pre-set test pressure and monitoring it for a pre-set time. The operator can adjust the leak tester settings from an easy to understand operator terminal.

Lip Flaming Attachment

The lip flaming attachment will flame treat the lip of the pail to ensure there are no plastic remnants.

Failed Pail Diversion

If a pail has failed the leak test station, it will be diverted to a rejection bin.

Pail Stacker

The stacker stacks pails to a maximum height of 48”.

Gravity Conveyor and Stack Accumulation

The conveyor moves the finished stacks into the stack accumulation, ready for packaging.

Optional Machines and Features

Square/rectangular pail orientation with actuated flame treatment

With this feature, the square/rectangular pail types are orientated to the handle mounting hole. The pails are then flame treated by a cam actuated flamer, which traces the shape of the pail.

This option provides more consistent flame treatment.

Pail Lifter

The pail lifter takes the pails from the catcher and lifts them to the hot stamping machine. The pail lifter elevates pails from a lower conveyor up to the in-feed height of the hot stamping machine or other equipment.

Pail Stacker

The stacker takes the finished product and stack it to a maximum of 48”. The stacker can be tooled for different pail sizes. Also, handle or handle-lobe orientation.

Ready for a quote?

Ready for a quote? Contact us today!

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Need our Parts and Repair Requisition Form? Click here!

102-17941 Roan Place,

Surrey, BC Canada V3S 5K1

Phone: (604) 576-6000

Fax: (604) 576-6097

Martin Automated Systems’ plant is in beautiful British Columbia, Canada. Located in Surrey, a suburb of Vancouver, we are a 45-minute drive from Vancouver international airport (VYR) and a 15-minute drive from the Pacific Highway border crossing.