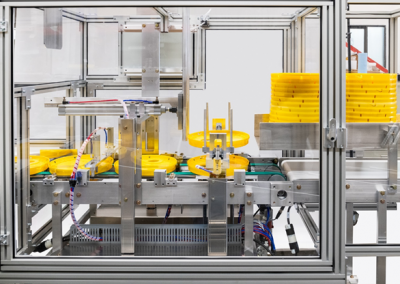

Undermold Lid System

The Martin Automated undermold lid system is designed to orient lids molded with a four-cavity stack mold. The system starts with a lid catcher. And the lids are conveyed out from under the molding machine in single file with the lid’s bottom side up. The ultimate purpose is to convey the lids to a gasket and spout installing machine. The lid stacker provides a buffer if the automated lid system is halted. To watch the function of the machine, please see the video.

Operation Summary

- Take out system orients the lids from under the mold.

- Incline conveyor that conveys the lids up to the stacker’s elevation.

- Transfer conveyor to bring the lids to the entrance of the lid stacker.

Features

- Festo cylinders

- Groschopp motors

- Conveyors use Ammeraal Beltech belts

- Catcher bucket is made from stainless steel

- The lid catcher and lid stacker are individually controlled

Ready for a quote?

Ready for a quote? Contact us today!

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Need our Parts and Repair Requisition Form? Click here!

102-17941 Roan Place,

Surrey, BC Canada V3S 5K1

Phone: (604) 576-6000

Fax: (604) 576-6097

Martin Automated Systems’ plant is in beautiful British Columbia, Canada. Located in Surrey, a suburb of Vancouver, we are a 45-minute drive from Vancouver international airport (VYR) and a 15-minute drive from the Pacific Highway border crossing.